Disk is a medium used for storing data. The base of hard disk is made up of firm and durable materials. The aluminum alloy (or glass) surface of disk is covered by magnetic powders and the surface is made to be very smooth. The magnetic powders are divided into several concentric circles (which are called tracks).

There are numerous magnets placed randomly on the track of each concentric circle. The magnets represent the status of 0 and 1. When they affected by magnetism from the head, the array direction will be changed as well.

Each magnet can be used to store information by controlling the direction of some magnets by the magnetism of the head.

Name: disk

Catalog

1. Structure characters of hard disk

2. Material of disk

Material of Al alloy substrate

Material of glass substrate

3. The amount of disks

4. The capacity of disks

1. structure characters of hard disk

Nowadays, disks are mainly created by film composite technology. The components of dielectric firm are: lubricating layer, carbon coating, magnetic layer, buffer layer or bottom layer and substrate.

Acting as mechanical and chemical protection, lubricating layer and carbon coating layer can protect the underlying magnetic layer; which is a multi-film structure made of CrCoTa,CoNiPt and CrCoPtTa; the buffer layer can improve the performance of the magnetic layer. The surface energy and roughness will affect the growth of buffer layer. So, the performance of magnetic layer can be optimized and improved by processing the substrate surface precisely.

2. Materials of disk

During the process of working and transporting, disk will suffer forces from many aspects, such as the disk gravity, centrifugal force caused by high-speed rotating of spindle, the turbulence force to disk when rotating with high-speed, and so on.

The disk also can be impacted by the vibration of a variety of machines in the process of transporting and being taken along. Particularly in the laptops and portable computers using hard disk, except for suffering the normal force from executing start / stop, the impact to disk from magnetic head will be extremely increased due to outside vibration. This requires disks should be possessed of high quality of surface hardness and impact resistance.

In the whole structure of disk, as magnetic layer, lining layer and lubricating layer are using film structure, the mechanical property of disk is mainly provided by substrate. Therefore, the chosen substrate must have certain mechanical strength and surface hardness.

The high-speed rotating of disk does help to read and write data quickly. However, as the speed increases, the force of air turbulence to disk within disk will be increased dramatically, and the disk will vibrate irregularly under its effect, thus the vibration will bring great harm to disk. What’s more, the amplitude will increase with the increase of speed of spindle. When the rotating speed is increased to a certain extent, the disk will be distorted, and the entire hard disk is damaged.

At present, the rotating speed of an ordinary hard disk is 5400/min, for some advanced hard disks, the rotation speed has reached 7200/min. Some companies like IBM and Hitachi have released disk with a speed of 2000/min, and the next target is 14000/min. Then, the force which disk suffers will be greater. Because the flexural property and the resonant frequency of material are relative to the elastic mold, the substrate material is required to have a greater modulus of elasticity for a faster speed.

Material of A1 alloy substrate Most disks are made of A1 alloy substrate. After A1 alloy annealing, the hardness is only 0.9GPa and the elastic modulus is only 70GPa. Because the mechanical properties of Al alloy itself is not sufficient to resist mechanical shocks caused by high-speed rotating of the head, the Al alloy is plated with a layer of NiP to enhance its mechanical properties.

But NiP layer’s uneven surface structure makes the flying height of magnet head unable to drop too low. When the hard disk surface has waviness, the magnet head demonstrates an up-and –down motion with the fluctuation of the high-speed rotating storage disk. If the wave height exceeds a certain degree, the magnetic head will no longer move with the waviness. It will collide with the surface of the disk substrate, and so-called head crush occurs. It can result in failure of disk device and error in reading and writing information.

On the other hand, head crush also occurs when there are numbers of microns on a memory hard disk surface. On the contrary, when the pits appear on the disk surface, the information cannot be written in completely, and this will lead to so-called “bit defect” or information read failure. In order to meet the ultra-high storage density recently, the distance between the magnetic head and the magnetic surface of the hard disk has been reduced to below 10nm.

So, in the disk surface polishing, it is required to produce the smaller head flying height and smooth surface without protrusions, scratches or pits.

3. Material of glass substrate

People want to get a better kind of substrate material to further improve the performance of hard disk drives. As a homogeneous dense and non-metallic material, glass is firstly chosen as the candidate of Nip/A1 substrate. The stiffness of glass is higher than that of aluminum alloy, and the covering of NiP layer can be saved.

However, as glass is a brittle material, one problem that should be solved in the high-speed rotation is the possibility of glass cracking because of the expanding of the crack on the surface. Glass-ceramic is considered as substrate of a hard disk to improve the defect of glass substrate. Glass-ceramic has excellent surface properties, mechanical properties, thermal stability and chemical stability.

Moreover, its strength and toughness are better than glass. Meanwhile, another character of glass-ceramic is the property is not only relative to the chemical composition of glass, but also determined by the thermal history of glass largely. This enables it to meet the requirements of different environments.

4. The amount of disks

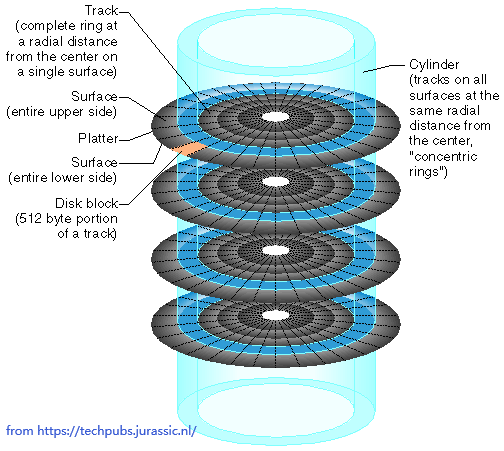

There will be multiple disks in one hard disk. Every disk has two sides and each side has its own read-write Head (H). Limited by hard disk size and production cost, the number of disks will be limited within 5. The number of disk is started with 0 from the bottom up. If the lowest disk has sides of 0 and 1, the upper disk next to it is marked with sides of 2 and 3.

5. The capacity of disks

The capacity refers to the capacity of each single disk, shorted by disk capacity. It is one of the very important parameters of a hard disk, and it can determine the level of the hard disk to some extent. Hard disk is composed of plurality of disks, and the disk capacity is the maximum of disk storage. Manufacturers can enlarge the capacity by two means. One is to increase the number of disks; the other is to increase the capacity of each disk.

What’s more, the increase of disk capacity can improve the whole capacity of hard disk as well as do good to the controlling of production cost to promote its working stability. The increase of disk capacity means manufactures should create more tracks. Although for manufactures, the demand for technique is quite high, the enhancement of track density represents the promotion of data density.

In addition, the increase of disk capacity can save cost to some extent. The increase of disk capacity is promoted gradually with the advancement of hard disk technology. The disk capacity of 40GB appeared in 2000, then in 2016, Seagate’s amazing 60TB SSD comes a year after Samsung’s 15TB SSD. Users now can spend much less money buying a large capacity drive these days.

However, with the increasing of hard disk capacity, more and more disk issues arise. Some users find their 3TB hard drive only uses 2TB, some report that their 3TB Drive Only Shows 746GB. Luckily, MiniTool offers the best solutions here.

User Comments :